- English

- Françai

- Español

- Deutsch

- Română

- العربية

- 한국어

- 日本語

- Italiano

- Português

- Gaeilge

- Dansk

- Čeština

- Русский

- Afrikaans

- Euskara

- Català

- Esperanto

- हिन्दी

- Ελληνικά

- Bahasa Melayu

- Polski

- Српски

- Kiswahili

- ภาษาไทย

- Tiếng Việt

- Türkçe

- Svenska

- Cymraeg

- Slovenčina

- Latviešu

- Malti

- Magyar

- Galego

- ગુજરાતી

- Eesti Keel

- বাংলা

- Shqip

- беларуская мова

- Nederlands

- Tagalog

- ქართული

- Íslenska

- Kreyòl Ayisyen

- Lietuvių

- Norsk

- slovenščina

- தமிழ்

- Українська

- ײִדיש

- اردو

- తెలుగు

- فارسی

- македонски

- ಕನ್ನಡ

- Bahasa Indonesia

- עברית

- Suomi

- Hrvatski

- Български

- Azerbaijani

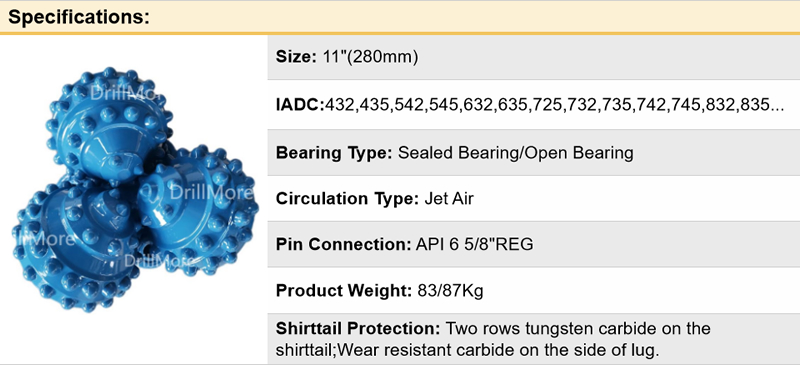

Tricone Bit Blast Drill Bit 11 Inch for Copper Mines

Tricone Bit Blast Drill Bit 11 Inch for Copper Mines

Rock drilling tools

Tricone bit

Mining

DrillBits

Tricone Bit Blast Drill Bit 11 Inch for Copper Mines

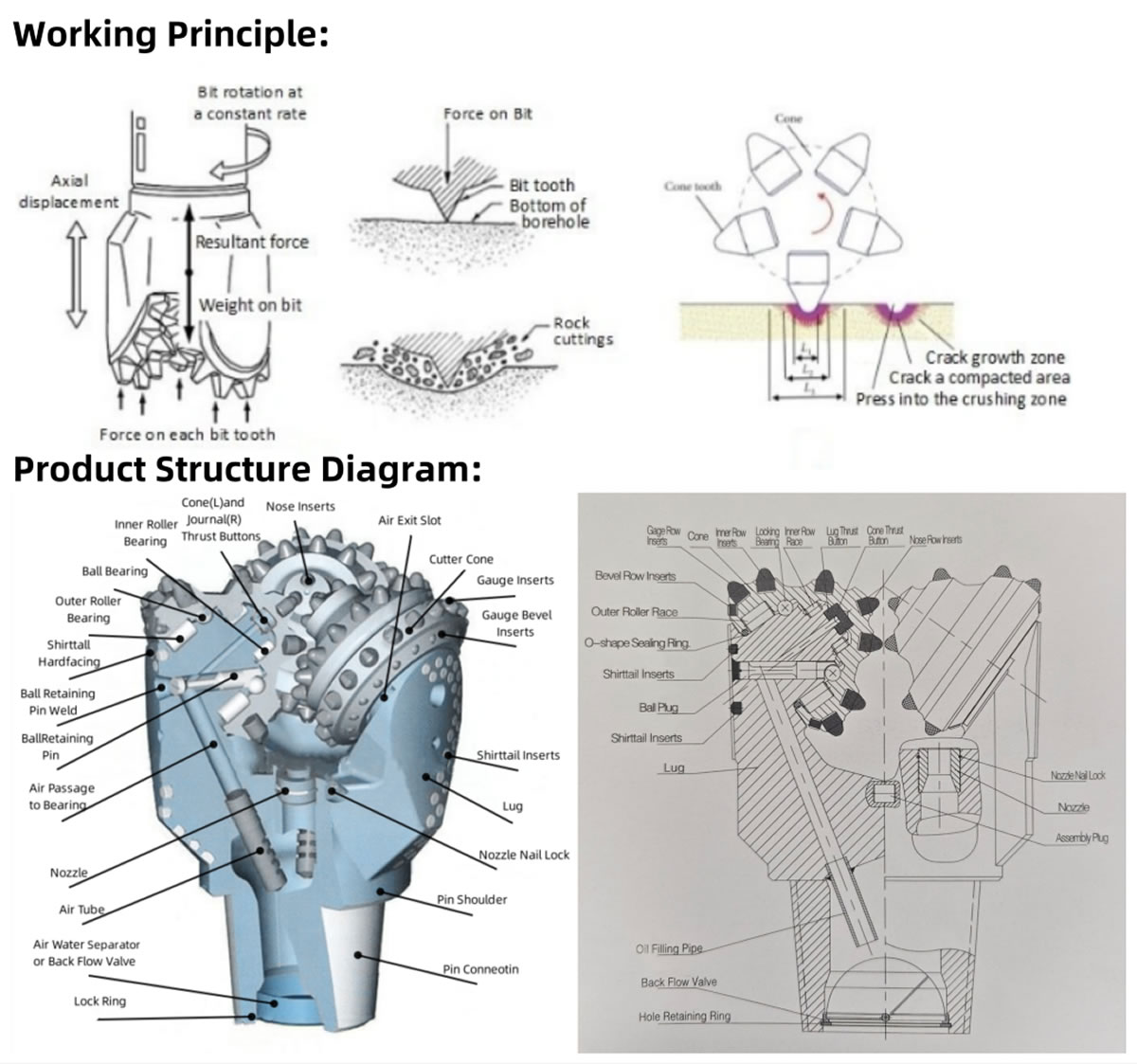

The mining-grade tricone bit is specifically engineered for efficient drilling in mining blast holes. Its unique gear design and material selection ensure stability and reliability in complex geological conditions. Widely deployed in mining operations, geological surveys, and blasting activities, it can drill through various types of rocks, including hard rock, soft rock, and sandstone. Its exceptional performance and durability make it the preferred tool for mining drilling operations.

Mining Grade Tricone Bit Operation Guide

Safety Operation Procedures:

1. Ensure all operators are trained and equipped with proper personal protective gear before starting operations.

2. Before the operation, thoroughly check the drilling equipment and Tricone Bit to ensure all safety measures are in place and functional.

3. Follow the operation manual and safety regulations strictly to ensure compliance with standard procedures.

Operation Procedures:

1. Tricone Bit Installation:

- Use appropriate tools to install the Tricone Bit onto the drilling equipment securely.

2. Equipment Debugging:

- Start the drilling equipment and gradually increase speed to the operating range.

- Check Tricone Bit rotation for smoothness and watch for abnormal noises or vibrations. Adjust equipment speed to match geological conditions.

3. Drilling Operation:

- Slowly lower the Tricone Bit into the borehole for safety and stability.

- Begin drilling operations, gradually increasing depth and speed based on geological conditions.

- Continuously monitor drilling parameters and make adjustments for safety and efficiency.

4. Shut down Procedure:

- Gradually reduce rotation speed and slowly withdraw the Tricone Bit from the borehole when stopping drilling.

- Shut down equipment and perform necessary safety checks and maintenance.

- Disassemble the Tricone Bit for cleaning and inspection.

Maintenance:

1. Regular Cleaning:

- Clean the Tricone Bit thoroughly with water after each use to prevent corrosion and wear.

2. Lubrication Maintenance:

- Please be sure to gently lubricate the Tricone Bit according to the operation manual.

3. Component Inspection and Replacement:

- Regularly inspect gears and bearings, replacing worn or damaged components promptly.

Troubleshooting:

1. Abnormal Noise or Vibration:

- Immediately stop operations and inspect the Tricone Bit if abnormal noise or vibration occurs.

2. Decreased Drilling Efficiency:

- Address any significant reduction in drilling efficiency promptly to avoid disruptions.

DrillMore Rock Tools

DrillMore is dedicated to the success of our customers by suppling drilling bits to each application.We offers our customers in the drilling industry many

options, if you do not find the bit you are looking for please contact our sales team at following to find the correct bit for your application.

Head Office:XINHUAXI ROAD 999, LUSONG DISTRICT, ZHUZHOU HUNAN CHINA

WhatsApp: +86 199 7332 5015

WhatsApp: +86 193 1332 3238

Email: info@drill-more.com

Call us now!

We are here to help.